Don’t Let Your Fried Foods Fry Your Reputation: Filtration for Consistent Flavor and Quality

For industrial food production companies, ensuring taste and flavor aren’t lost to oil degradation is a top priority – not only for day-to-day customer satisfaction but for maintaining a reputation as a quality provider of fried foods.

We understand that after a while, your frying oil doesn’t stay clean. It starts picking up burnt bits, fatty acids, and other contaminants that can really mess with the taste and look of your fried foods.

Nothing pushes customers away faster than when what they’re eating doesn’t taste quite right. If those flavor swings become too wild, you can bet it’ll sour your image in no time. To make matters even worse, other foods cooked in the same oil can also be affected when not filtered out properly, further compounding the problem.

Wondering how to keep your food so tasty and satisfying that it draws people back time and again? By putting these steps in motion, Imagine a system that filters out the bad stuff with unmatched efficiency – that’s exactly what we’ve got here.This process clears away unwanted contaminants and at the same time stretches out how long you can use your frying oil.

By removing contaminants and ensuring consistent oil quality, effective filtration helps you deliver the mouth-watering fried foods that your customers crave, all while protecting your brand’s reputation.

A Fried Food Fiasco

When it comes to frying, the quality of the oil is just as important as the quality of the food itself. As oil is repeatedly heated and used, it begins to break down and accumulate a variety of taste-altering elements that can wreak havoc on the flavor and quality of your fried foods.

Burnt particles, created when food particles become overcooked and charred, can impart a bitter, unpleasant taste to your fried foods. Tiny particles have a way of turning the oil dark, making it something customers would rather not see.

Fatty acids, released as the oil breaks down, can cause the oil to become rancid and develop off-flavors. These flavors can permeate the food, resulting in a less-than-desirable taste that fails to meet customer expectations.

Other contaminants, such as moisture from the food itself or even cleaning agents used on the fryer, can also contribute to the oil’s degradation and the fried food’s quality.

The accumulation of these taste-altering elements not only affects the flavor of the food but can also lead to inconsistencies in taste and appearance. Customers who receive a less-than-perfect product may be less likely to return, damaging your reputation and bottom line.

How High-Performance Filtration Handles

To combat the problem of taste-altering elements and maintain the quality of your fried foods, implementing a high-performance filtration system is essential. Filtration systems, like those offered by Oberlin Filter, are designed to remove the contaminants that can degrade oil quality and affect food taste.

For example, Oberlin Filter’s automatic pressure filtration systems can remove up to 99.99% of total suspended solids from liquids, including burnt particles, fatty acids, and other contaminants. These systems can snag solids as tiny as 1 micron, making sure not a single speck escapes the cleanup in the oil.

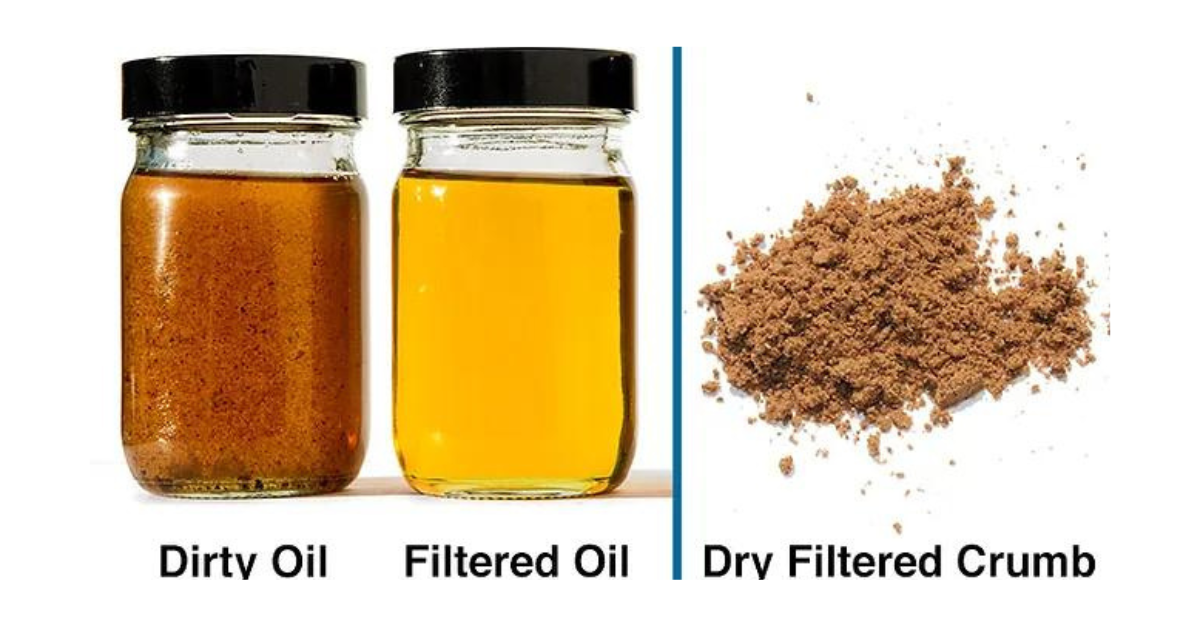

Imagine this – filters working overtime to pull out all the gunk from your oil. What you’re left with is nothing short of excellent; everything looks as it should, satisfying customers far and wide.

And when the oil is clean and free from taste-altering elements, your fried foods will maintain their desired flavor profile and appearance, keeping customers happy – and your reputation intact.

How High-Performance Filtration Works to Keep Your Fried Foods Tasting Great

Oberlin Filter’s high-performance filtration systems work by utilizing pressure to drive the frying oil through a fine filtration media, effectively removing contaminants and taste-altering elements. Ever wonder what keeps fried food from getting an unpleasant aftertaste? Industrial filters are to thank for saving the day and taste!

- Dirty frying oil is pumped into the self-contained filtration chamber under pressure.

- As the oil passes through the filtration media, solid particles as small as 1 micron (about 70 times smaller than the width of a human hair) are captured and retained on the surface of the media.

- Over time, the captured particles form a cake-like layer on the filtration media. Think of this cake layer as a superhero for your oil, snagging all those extra unwanted bits with ease when it’s under pressure.

- The high pressure (typically 30-40 PSI) forces the oil through the densely packed cake and media, resulting in an ultra-clean filtered oil free from burnt particles, fatty acids, and other taste-altering elements.

- The clean, filtered oil is then returned to the fryer, ready to cook up delicious, consistently flavored fried foods.

- As the filter cake builds up, the system automatically discharges the dry, solid waste without operator intervention, ensuring a continuously clean supply of filtered oil.

Using high pressure and a combination of filtration media and filter cake, Oberlin Filter’s systems can remove up to 99.99% of total suspended solids from your frying oil. With this top-notch filter doing its job, your oil stays sparkling clean. That means every batch of your product keeps looking and tasting great.

The Other Benefits of High-Performance Filtration

It’s not all about maintaining the taste and quality of your fried foods – implementing a high-performance filtration system can provide a range of other benefits for your food service business that satisfy customers and your bottom line.

Longer Shelf Life and Reduced Waste

High-performance filtration can help increase the shelf life of fried food products by removing contaminants and extending the life of the oil. Using cleaner oil can keep your products tasting fresh for a longer time, cutting down on the waste and shrinking the losses that come from product going bad.

Cost Savings

While investing in a high-performance filtration system may seem like a significant upfront cost, it can lead to substantial cost savings over time.

By extending the life of your frying oil and reducing the frequency of oil changes, you can save money on oil replacement costs. In addition, consistently producing high-quality fried foods, you can reduce waste and minimize losses associated with customer dissatisfaction and product returns.

Enhanced Reputation and Customer Loyalty

Consistently delivering high-quality, great-tasting fried foods can help to enhance your brand’s reputation and foster customer loyalty.

When customers know they can count on your brand for delicious, perfectly fried foods every time, they are more likely to return and recommend your business to others. Imagine seeing more products flying off the shelf while everyone’s chatting up how great you are – that’s the kind of branding gold we’re after here.

Improved Food Safety

It should go without saying that high-performance filtration can help improve food safety. Think of filtration systems as guardians for your frying oil. They swoop in to remove contaminants and protect the oil from forming harmful substances, making every fry-up a bit healthier. Not only does it amp up the yum factor of your fried fare, but it also puts any safety worries to bed.

When Flavor Matters, Trust Oberlin

With an Oberlin Filter system in place, you can confidently serve your customers the delicious, consistently flavored fried foods they crave while protecting your brand’s reputation for quality and excellence.

Oberlin Filter’s advanced filtration technology removes up to 99.99% of total suspended solids, effectively eliminating the taste-altering elements that can degrade oil quality and compromise the flavor of your fried foods.

The Key Takeaways

- For that perfect bite every time, rely on advanced filtration to preserve the quality of your fried treats. Oberlin Filtration systems work hard to strip away the bad stuff and keep your frying oil fresh. This means every bite of fried food tastes just as fantastic as you want it to for your customers.

- Dropping some dough on high-efficiency filtering equipment means less spending over time plus major upsides like impeccable hygiene standards. And let’s face it – when your customers trust what they eat, they’ll stick around longer (and so will their friends).

- When it comes down to keeping flavors rich and foods top-notch, Oberlin Filter steps up with its innovative filtration tech. Using both high-pressure and various filtering materials ensures your products meet the mark every time.

Don’t let poor oil quality fry your reputation. Trust Oberlin Filter to help you maintain the delicious, consistently flavored fried foods your customers crave. Contact us today to learn more about how our advanced filtration systems can benefit your business

JOIN OUR INDUSTRY NEWSLETTER

Your source for expert filtration knowledge, tips, and solutions to keep your operations running smoothly.